I need to work on shaping the corners of the desk with the capitals attached. I saved the cut off from the front of each of the sides. These I used to make two of the four columns in the glue up. This was I hoped a good way to match the grain.

This is a sample one that I made for practise. I need to put this joint on the side of the column.

I traced the line on the side from the writing surface board.

I forgot to film it as I was making it. But first I used a table saw to cut away 7/16 from the side without getting too close to the lip on the bottom.

Then I used a hand saw to cut the 45 on the inside stopping before I hit the side.

Then I cut the flat with a hand saw again stopping before I cut into the joint.

Then I chopped out the waste with a chisel. It is not real pretty in the inside but it is not seen.

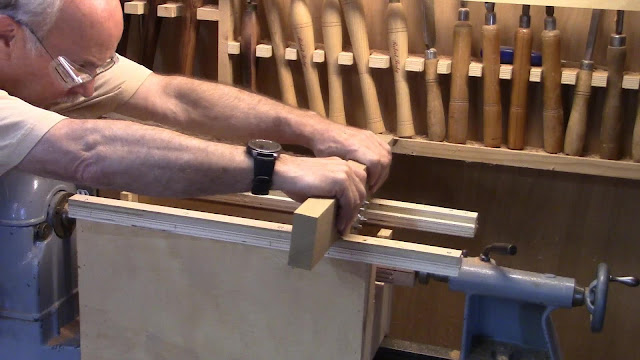

Now to test the fit with the finished piece.

Looks pretty good. I did a little paring on the inside.

I created the dividers using the dado set leaving 1/2 inch by 3/8 inch stub tenons.

I use a straight edge to trace the line for the slop of the front. I made the cut on my radial arm saw. I clamped the two sides together and made one cut for both sides. Here I am extending the slope to the corner for the cut off.

The top needs to be trimmed also so I trace the line on the side while it was assembled.

It requires two cuts, the second line is perpendicular to the first slope line. This is where the desk lid will be locked.

No need to change the blade slope since the cuts are perpendicular.

All set to glue up.

Next i'll work on the lid supports or lopers.